Set routings on kit Bills of materials

It often happens that you want to use kit BoM's within manufactured product BoM's in order to lighten the list of components for this manufactured product. When doing so, you would like to have the possibility to specify, for each kit component, in which operation they are consumed.

We will see the three use cases that you can face in these kinds of configurations.

Finished Product & Kit Component have the same Routing

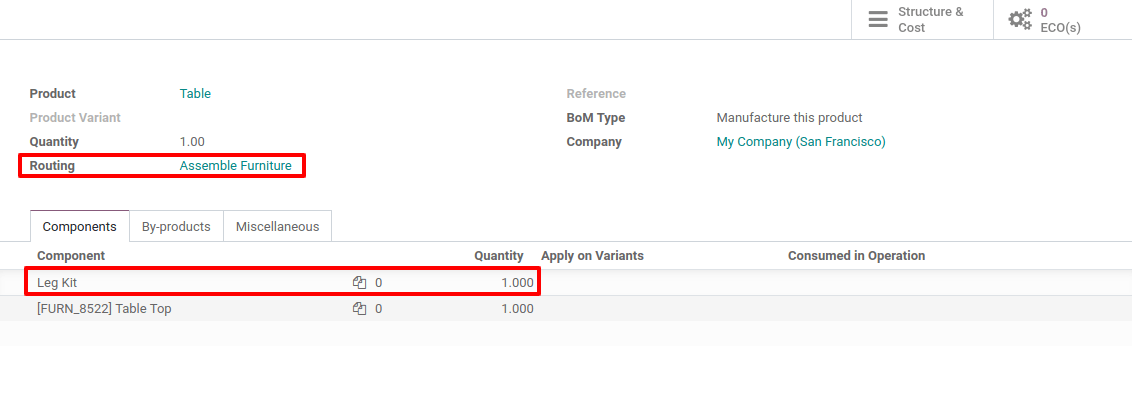

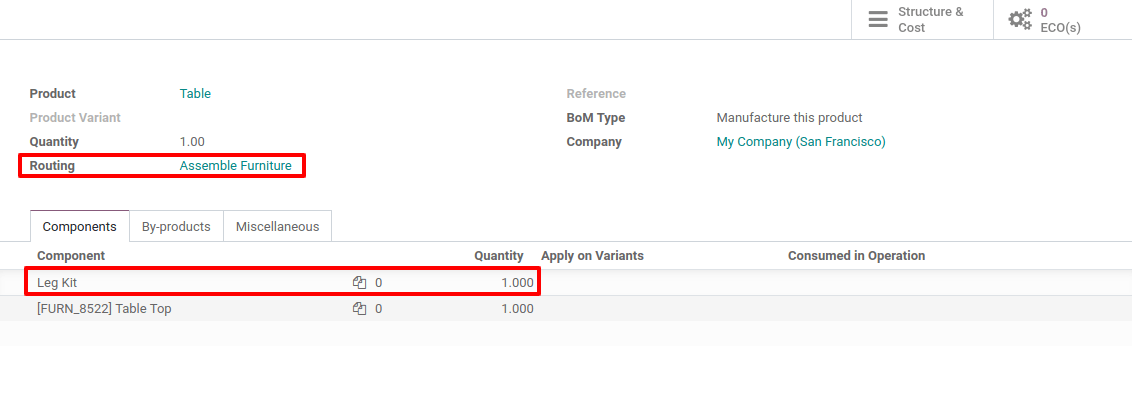

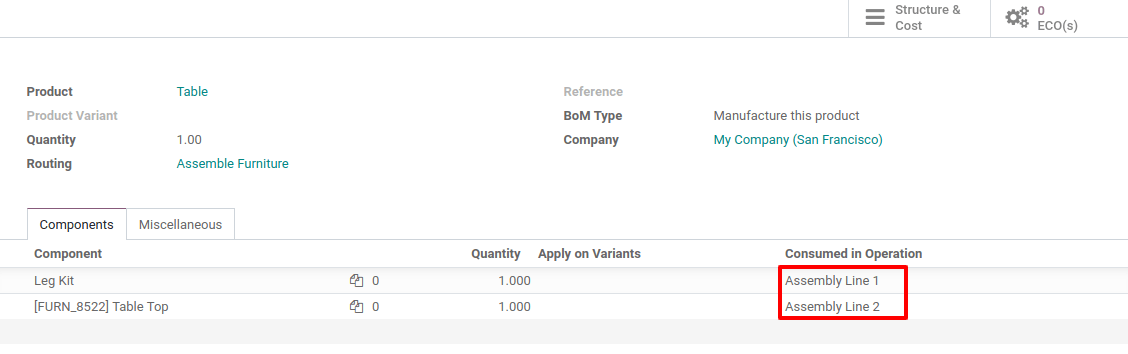

Create BoM for the Finished Product

Create a manufactured BoM for the finished product which includes a kit component. Set a routing on your BoM, for example, Assemble Furniture.

{.align-center}

{.align-center}

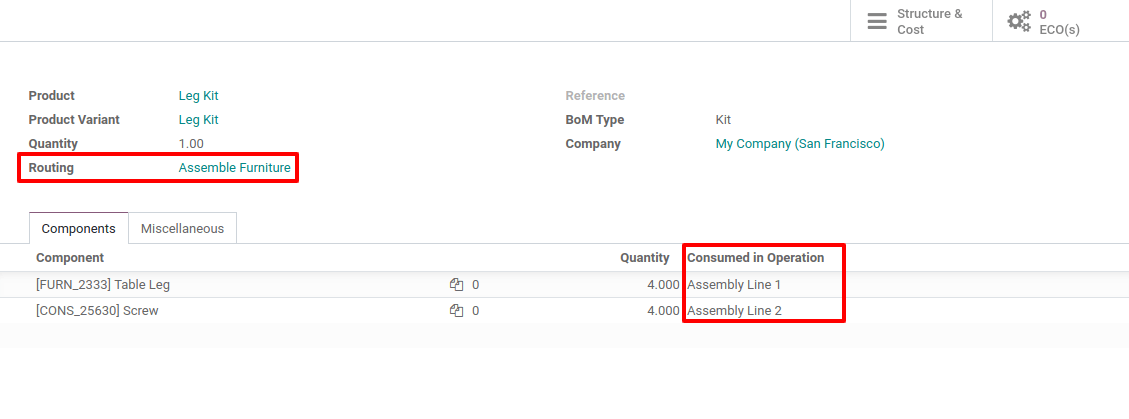

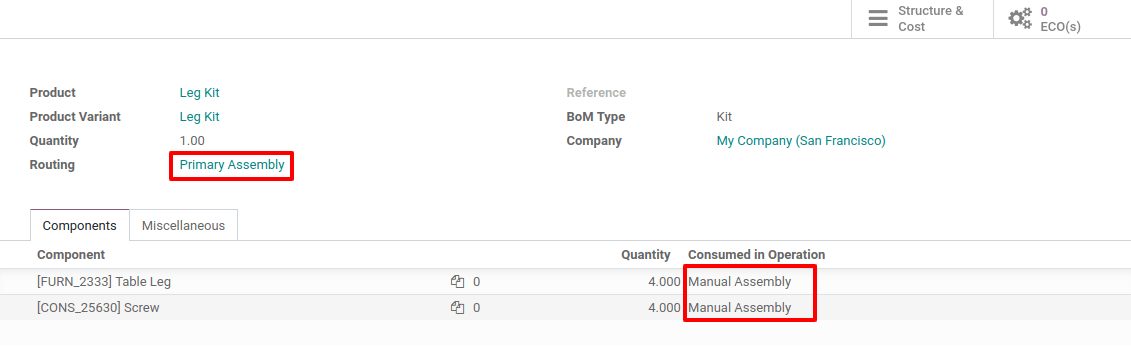

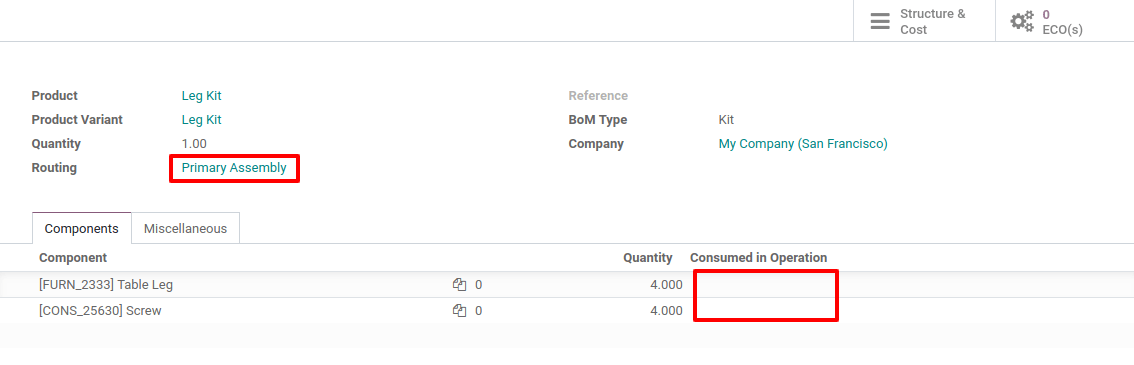

Create a Kit BoM for the Kit Component

Update the kit component to define its BoM. Make sure that the routing which is set on this BoM is the same one than on the Finished Product.

{.align-center}

{.align-center}

You can define the operations in which the kit components are used directly in the BoM of the kit.

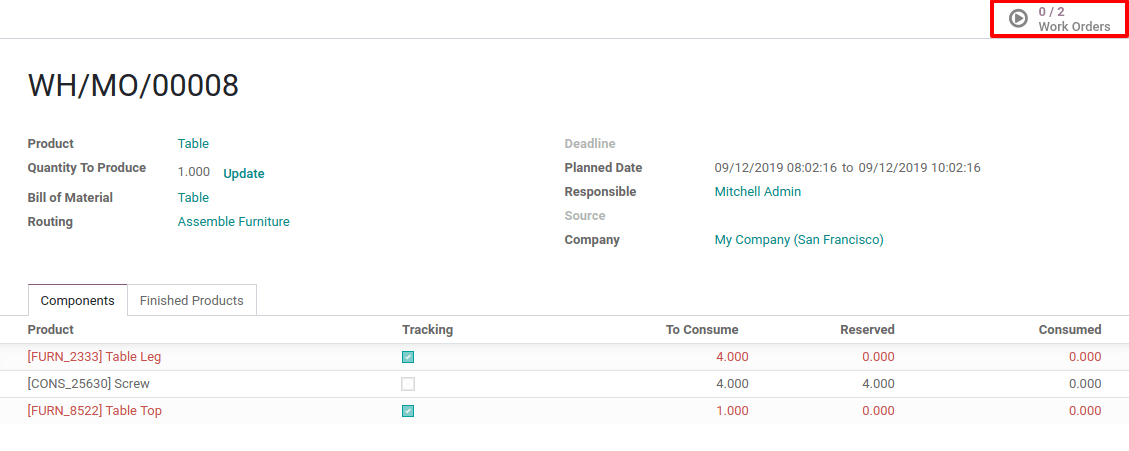

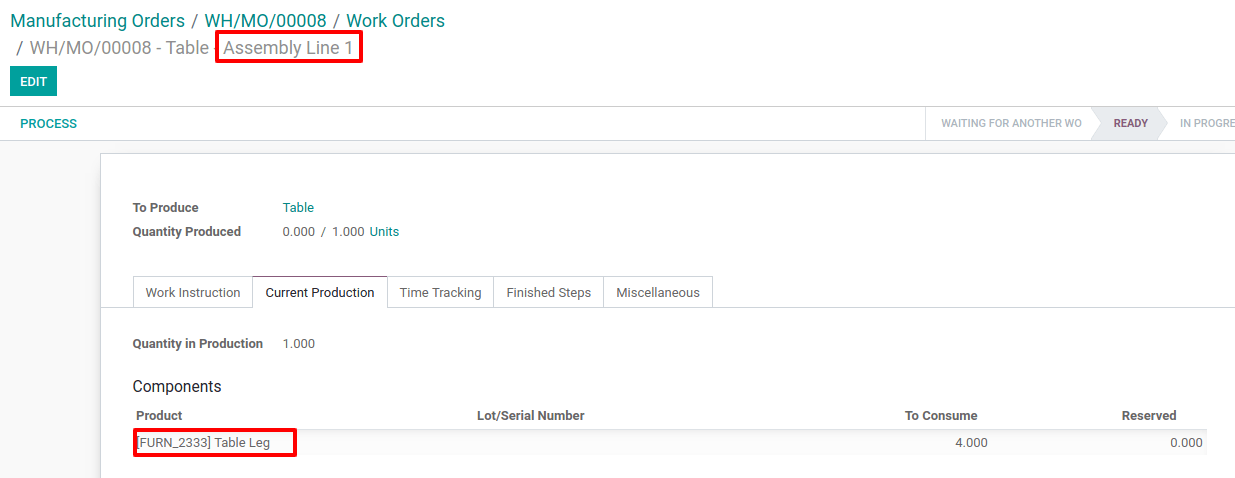

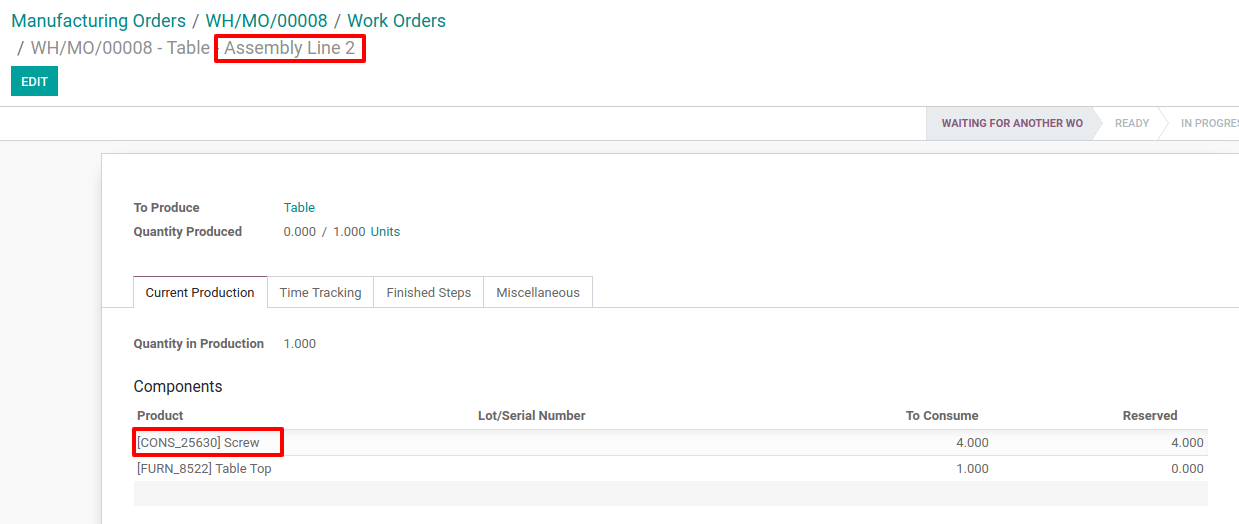

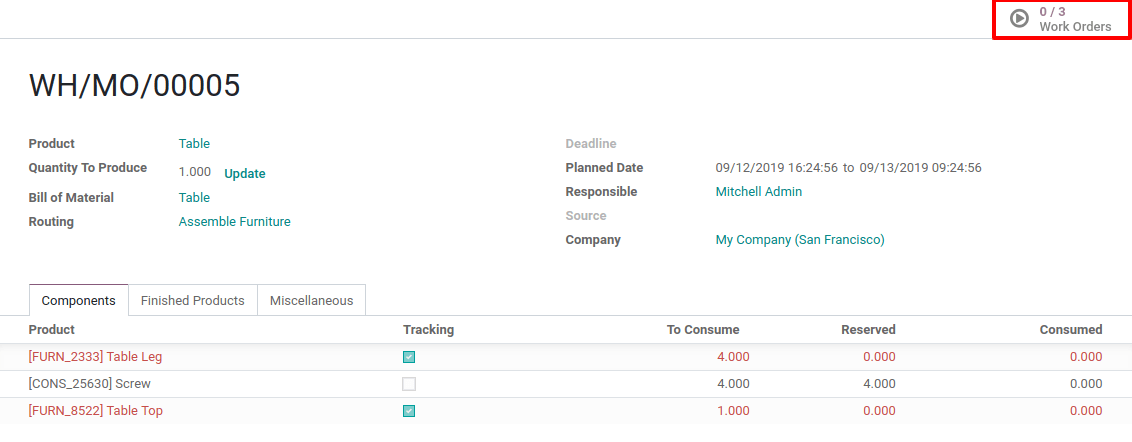

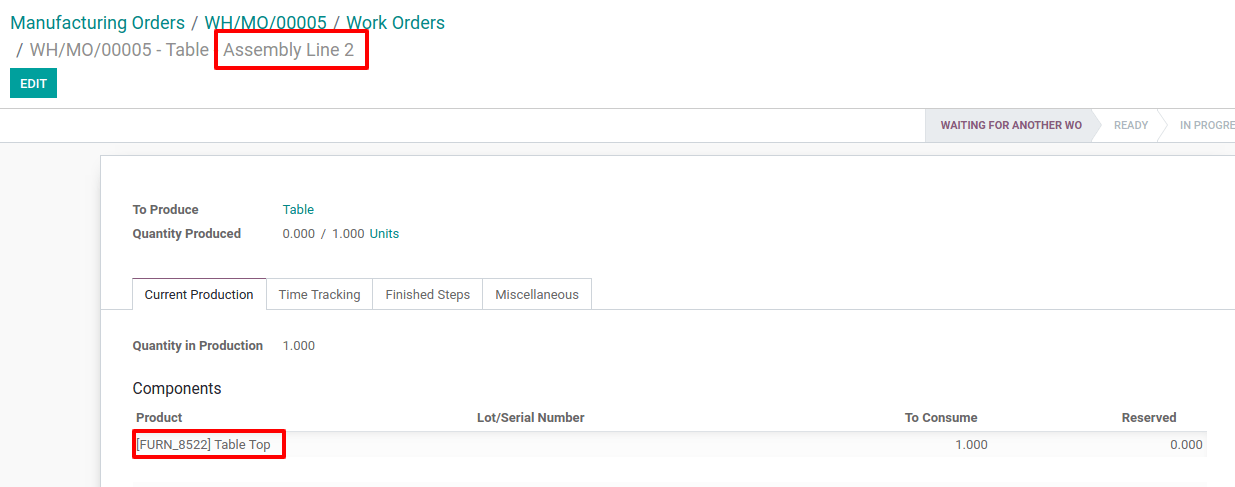

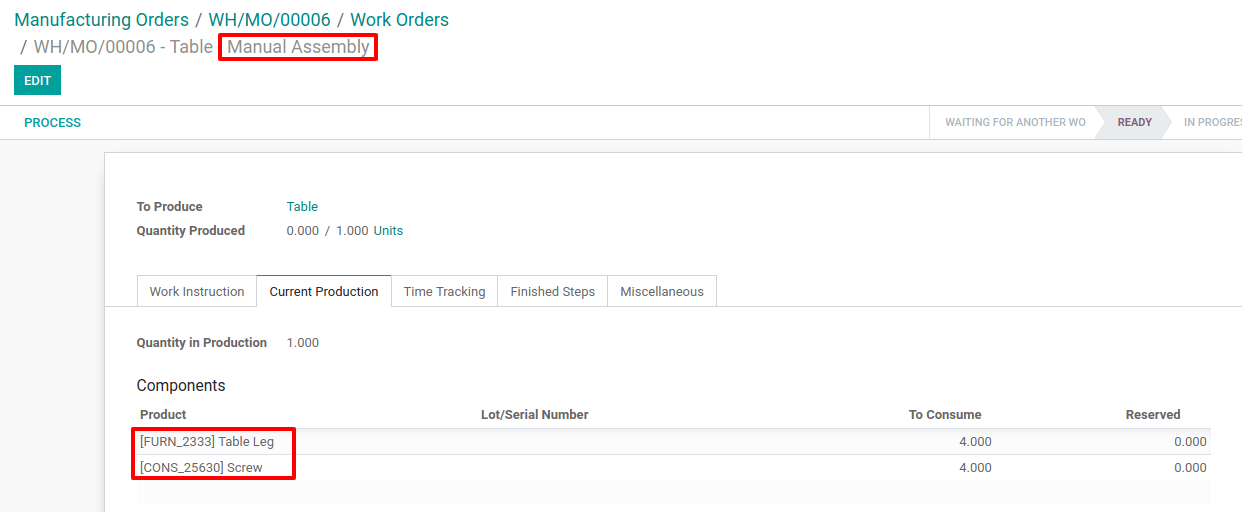

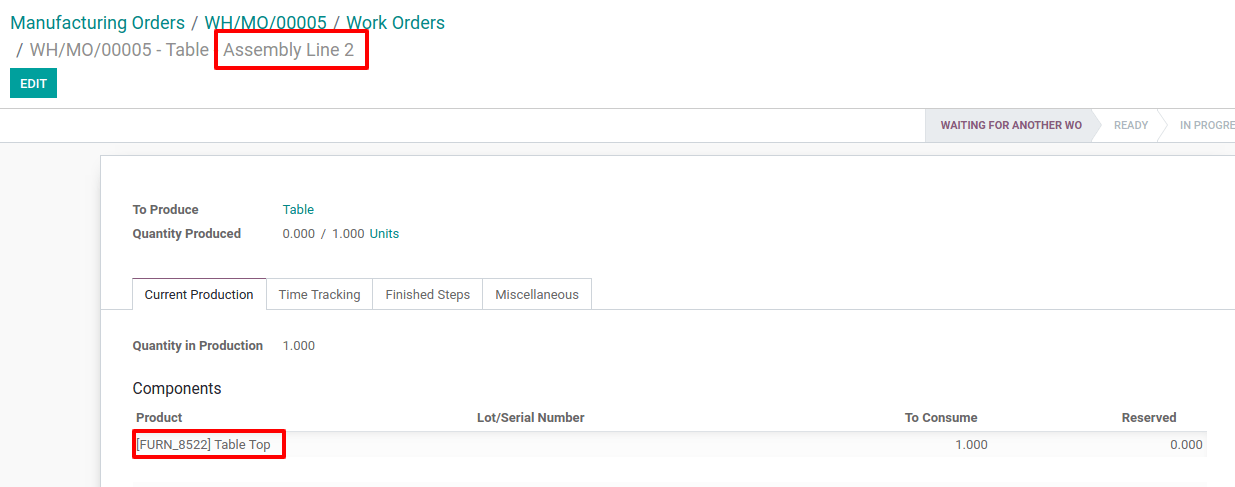

Manufacturing Order

In the list of components, the kit is split. Two work orders are created as we have two operations defined in the Assemble Furniture routing. The components of the kits are well consumed in the operations defined in the kit BoM.

{.align-center}

{.align-center}

{.align-center}

{.align-center}

{.align-center}

{.align-center}

Finished Product & Kit Component haven't the same Routing

Kit Consumption set on Finished Product BoM

Create BoM for the Finished Product

Create a manufactured BoM for the finished product which includes a kit component. Set a routing on your BoM, for example, Assemble Furniture.

{.align-center}

{.align-center}

Create a Kit BoM for the Kit Component

Update the kit component to define its BoM. In this use case, the routing which is set on this Kit BoM is different than the one of the Finished Product. Specify the operations at which the kit components are consumed in this BoM.

{.align-center}

{.align-center}

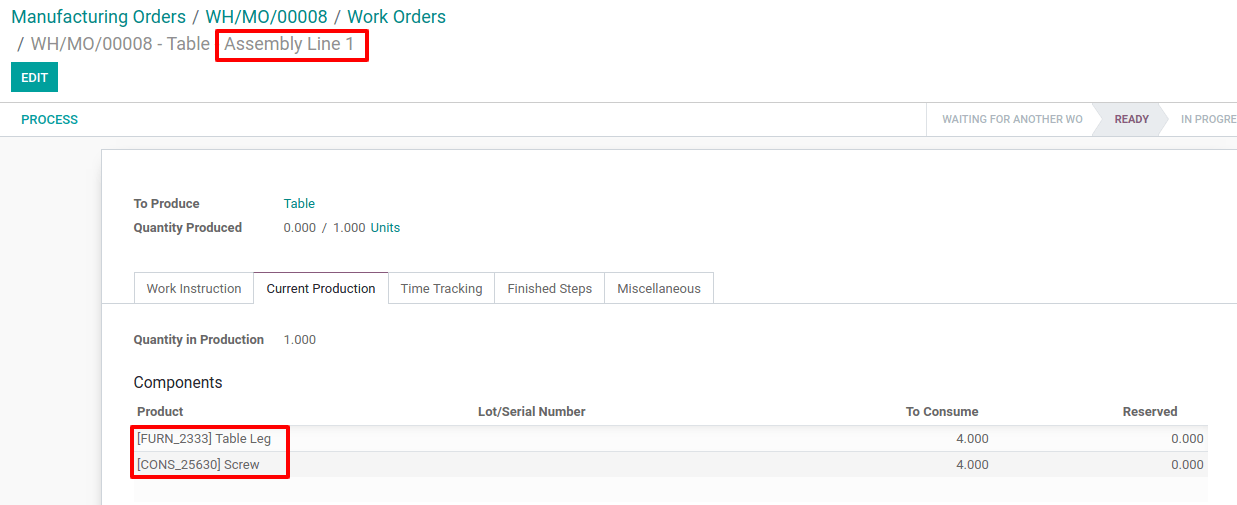

Manufacturing Order

When the manufacturing order is created for the Manufactured product, the kit is split among its components. When the manufacturing order is planned, three work orders are created in our case, one coming from the routing of the manufactured products, the two other ones coming from the routing of the kit BoM.

{.align-center}

{.align-center}

The components are all consumed during their respective operations.

{.align-center}

{.align-center}

{.align-center}

{.align-center}

Kit Consumption set on Kit BoM

Create BoM for the Finished Product

Create a manufactured BoM for the finished product which includes a kit component. Set a routing on your BoM, for example, Assemble Furniture. Precise the consumption of the components on this BoM.

{.align-center}

{.align-center}

Create a Kit BoM for the Kit Component

Update the kit component to define its BoM. In this use case, the routing which is set on this Kit BoM is different than the one of the Finished Product.

{.align-center}

{.align-center}

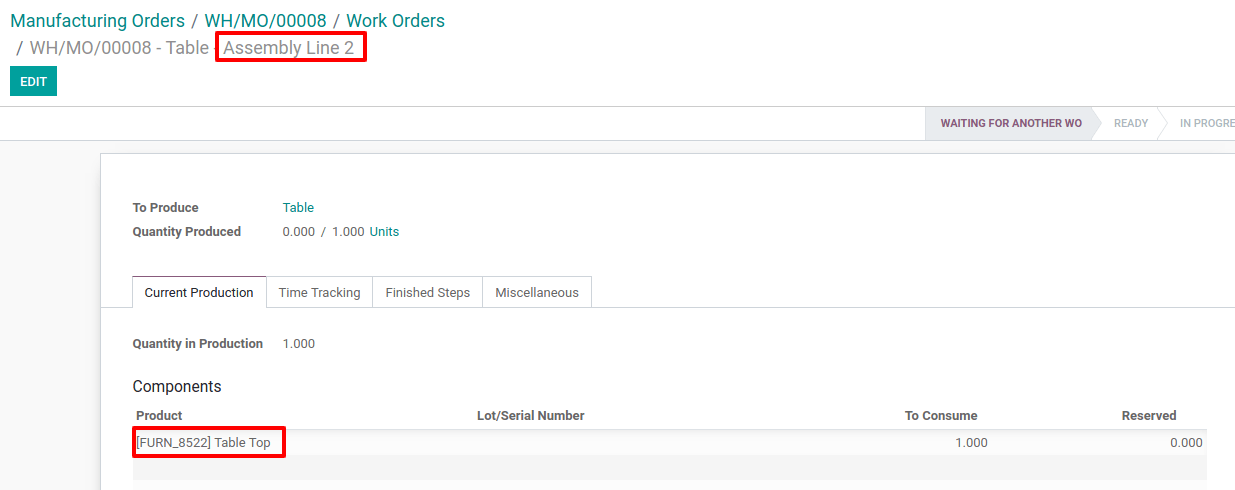

Manufacturing Order

When the manufacturing order is created for the Manufactured product, the kit is split among its components. When the manufacturing order is planned, three work orders are created in our case, one coming from the routing of the manufactured products, the two other ones coming from the routing of the kit BoM.

{.align-center}

{.align-center}

All the components of the kits are consumed during the first operation. The last component is consumed during the second operation.

{.align-center}

{.align-center}

{.align-center}

{.align-center}